Our Strengths

5G Smart Workshop

- Production Equipment Connectivity & Control

- Real-time Monitoring in Quality Control Center

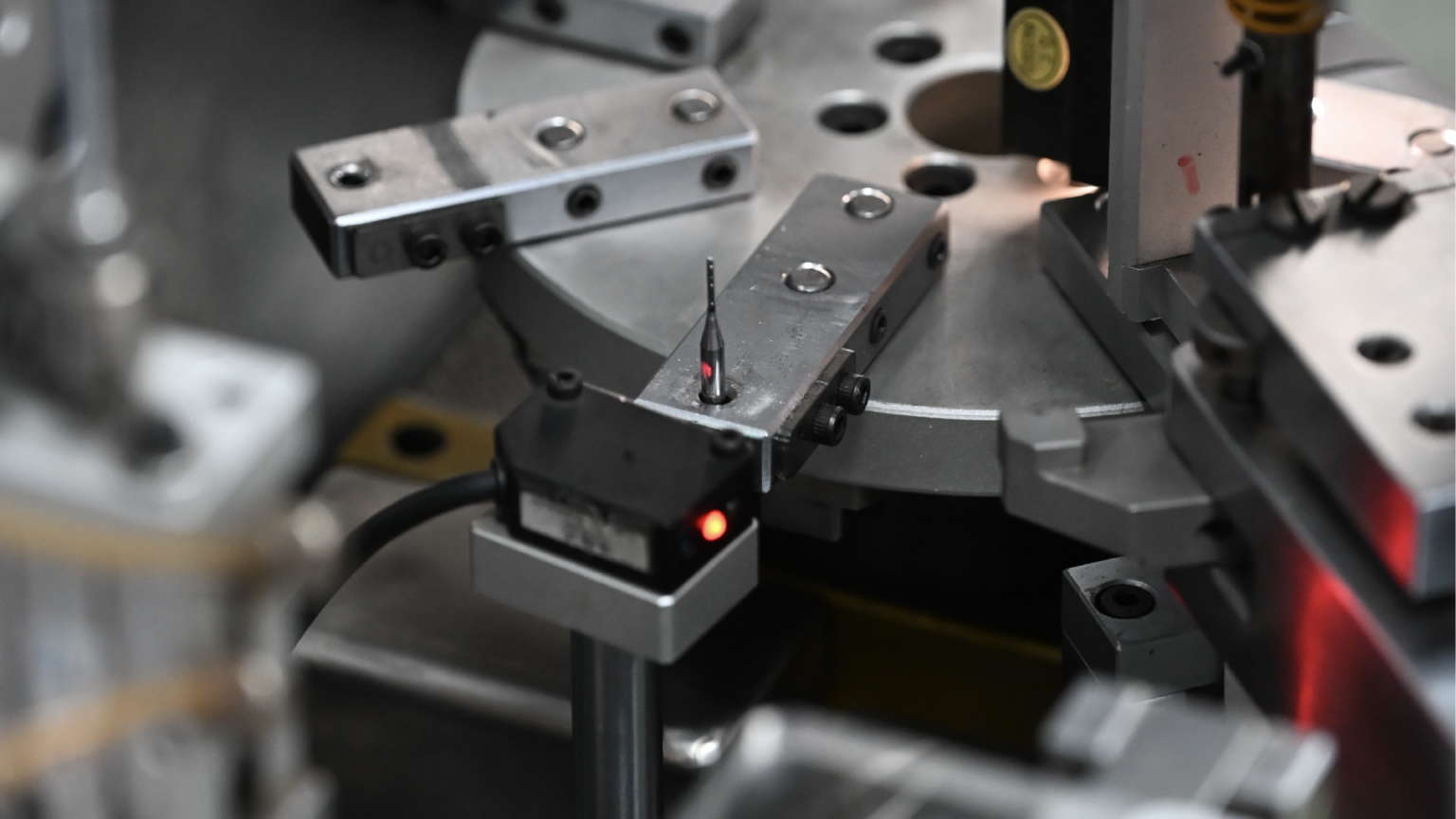

- One-click Rapid Inspection of Milling Cutter Parameters

- Real-time Compensation Technology for Grinding Wheel Parameters

Resizing Technology

- Professional Resizing Technology – used Blade Tooth Removal: 0.4mm

- Taking a 2.0mm used cutter as an example, industry-standard processes allow for two resizing, while our group’s process allows for three resizing.

SG Tungsten Steel Material Inspection

- Independently Developed Tungsten Steel Inspection Equipment

- Classification & Selection of Tungsten Steel from Different Manufacturers

- Welding & Parameter Settings Based on Different Manufacturers’ Materials

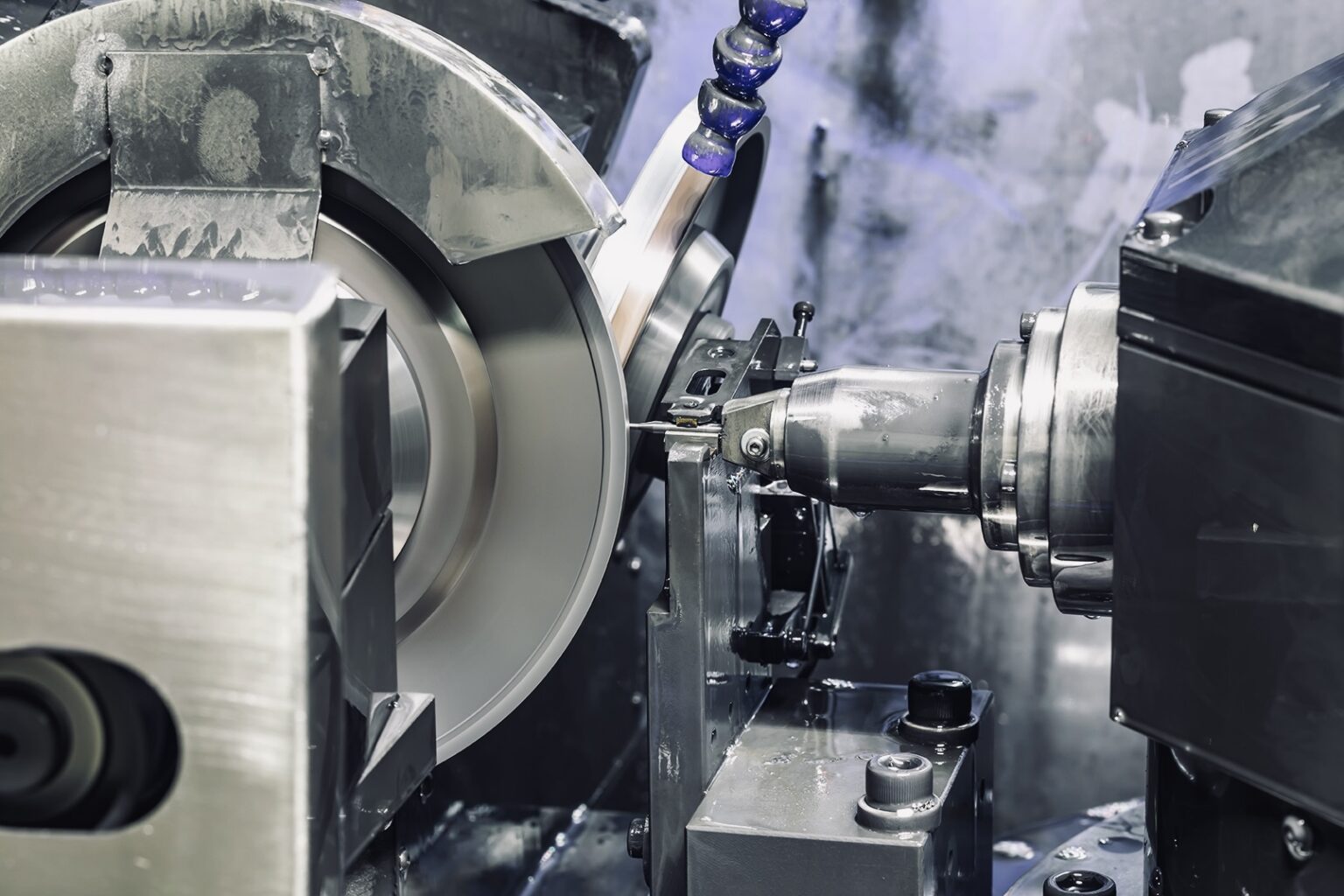

In-house Tungsten Steel Shank Material Production

- Group-owned Tungsten Steel Shank Material Production Company

- Ensuring Stability of Shank Material Performance

- Reducing Production Costs

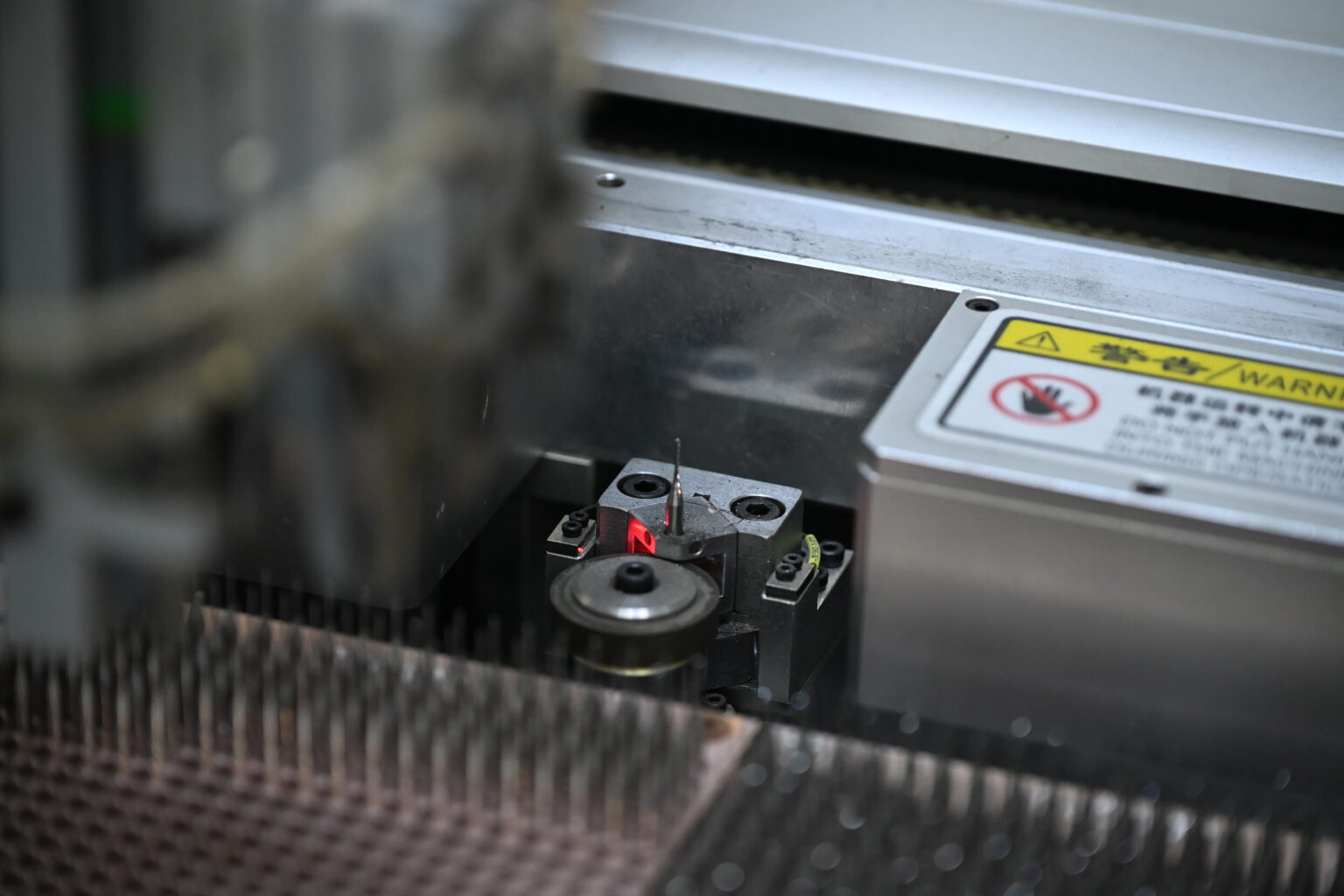

In-house Production Equipment Manufacturing

- Independently Developed Key Production Equipment – “Four-Station Slotting Machine”

- Implementation of Regular Maintenance Plans for In-house Production Equipment

Technical Solutions

- Extensive Technical Solutions for a Broad Customer Base

- Tooling Recommendations Based on Customer Processing Conditions

- Solutions for Issues Such as White Edge and Copper Tearing

- Simulating Customer Processing Conditions with Forming Machines for Testing